How Does Your Enterprise Labeling Stack Up?

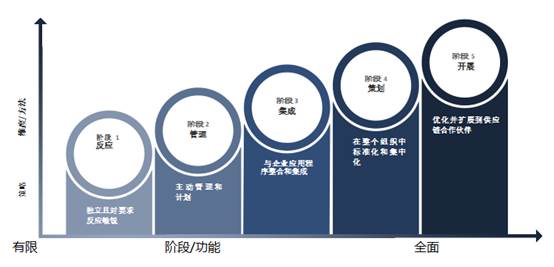

5 Stages of Labeling - Find Out Where You Fit

In order to build a roadmap towards labeling excellence you must first understand the stages of labeling maturity. Fortunately, the Maturity Model for Enterprise Labeling offers just that - a framework for improvement in the area of labeling throughout your organization.

Now you can use this model to create a baseline and define a clear path toward Enterprise Labeling excellence.

This report shows you how to:

ENTERPRISE LABELING MATURITY MODEL

A Framework for Labeling Excellence

Introduction

The Maturity Model for Enterprise Labeling provides a framework for improvement in the area of labeling throughout your organization. It highlights your capabilities and processes over five specific stages of maturity, offering a roadmap for improvement and providing a clear picture of the areas which need to be addressed for continuous progress. Your organization can assess technologies and existing methods through this diagnostic tool, which allows you to measure current effectiveness of your labeling and determine what capabilities are needed to increase labeling efficiencies and enable business transformation.

This model has been developed as a result of working with companies in the labeling space for more than 30 years to identify the most critical areas of development and growth when it comes to supply chain labeling. That work, with thousands of leading global companies from across a wide range of key industries, includes decades of research, extensive surveys and feedback from domain experts. This has led to the creation of the Five Stage Maturity Model for Enterprise Labeling. Now, supply chain, logistics and business stakeholders can use this model to create a baseline and define a clear path toward Enterprise Labeling excellence.

In order to build a clear roadmap towards Enterprise Labeling maturity, this model includes five separate maturity levels, based upon key criteria referred to as ‘dimensions.’ Once you measure how well you’re managing labeling within key dimensions, you can chart a course for your optimal labeling end state. With this assessment, you can identify any potential roadblocks, operational gaps or other areas of concern so you can prioritize accordingly. Working with the Enterprise Labeling Maturity Model will give you a:

The Five Stages of Enterprise Labeling Maturity

Not all businesses have the same labeling demands or progress at the same pace across the Enterprise Labeling continuum. Additionally, not all companies have the same global requirements, need to scale labeling or increase capabilities to support evolving business demands. However, all businesses need to ensure that their labeling requirements are optimized for business and supply chain efficiency as well as future growth.

And the first step is to understand your level of labeling maturity and chart a course for the highest level that

makes sense for your business. Below is a brief description of each maturity level.

Companies at this stage tend to have manually driven processes and largely siloed initiatives which cause them to be reactionary in meeting their labeling demands. Generally, each location has autonomy over its own labeling, resulting in a variety of different solutions for labeling used across an organization. Having this control enables them to be agile and responsive, albeit only at the local level. At this stage there is no integration or reliance on data exports from enterprise applications resulting in lack of accuracy and consistency. This approach involves more time and people to execute labeling

Stage 2 - Proactively Manage and Plan

In stage 2, companies are working toward standardizing their labeling on one solution and are beginning to add some level of automation. Although the labeling function is being managed more proactively, it is still highly localized with silo deployments and individual facilities maintaining control. Labeling at this level takes more time and energy and maintenance to execute due to a lack of automation and standardization. Variable and dynamic content remain a challenge.

Stage 3 - Consolidate and Integrate

At stage 3 the labeling function becomes integrated with data sources for increased accuracy and consistency. Centralization becomes more of a focus while business logic begins to play an increasing role while more variable content is used. The move to automate and integrate offers great benefits and increases efficiencies in labeling overall, offering a path to more optimized labeling company-wide. However, executive level awareness of labeling and its importance is limited as is overall labeling visibility.

Stage 4 - Orchestrate Across the Organization

At stage 4, labeling goes beyond integration and is standardized and centralized across the organization, with fully automated workflows and data-driven labeling capabilities orchestrated throughout. Executive awareness of labeling increases along with increased visibility through business intelligence. This stage brings increased efficiencies across the enterprise and facilitates global scaling. Companies at this stage begin integrating and sharing content, processes, and workflows between Enterprise Labeling and Artwork Management.

Stage 5 - Optimize and Extend Beyond the Organization

At this final stage, companies begin extending their labeling and labeling processes beyond their organi- zation. Labeling is highly automated and integrated to ensure accuracy and consistency while optimizing efficiency and resource costs. This stage, which includes both internal and external stakeholders, highlights the importance of labeling to the overall supply chain and enables companies to use labeling as a competitive advantage. Companies use a digital platform to create, manage and print complex labeling and artwork globally, including suppliers and partners.

The Dimensions of Enterprise Labeling Maturity

Organizations can succeed in creating fully optimized labeling as part of their supply chain strategy by advancing maturity in each of the following nine dimensions outlined below. When considering the nine dimensions included in the Enterprise Maturity Model, three distinct categories emerge as logical groupings for these areas of labeling maturity. They include Foundational, Operational and Governance as explained in detail below.

Figure 2. Categories of Enterprise Labeling Maturity

FOUNDATIONAL DIMENSIONS

The first category examines the Foundational capabilities involved in implementing an optimized approach to Enterprise Labeling. These core capabilities, including standardization and centralization, create the blueprint for how your labeling should be deployed and accessed enterprise-wide. Dimensions in the Foundational category help define the scope of labeling across your organization as well as architecture - showcasing

the necessity of collaboration between packaging and labeling along the product lifecycle, from product development all the way through the supply chain to the end user.

Standardization

Deploying a single labeling solution across your business enables labeling consistency and dramatically improves oversight. Rather than managing multiple systems, a standardized approach enables companies to support enterprise-wide labeling changes while streamlining maintenance. In addition to reducing cost and improving efficiency, having a single, scalable solution for labeling facilitates expansion to new global locations. Also, by taking a standardized approach, companies can ensure that a common set of labels, content, applications and data sources are used across the supply chain.

Centralization

Centralizing labeling across multiple locations and geographies ensures label consistency across your supply chain. A centralized labeling model provides access to labeling at a primary location, supports adherence to corporate standards and enables rapid and universal label changes throughout your organization. This type of centralized approach, which offers failover to individual locations with continuous uptime, is also essential in supporting business continuity in the face of any potential supply chain disruption.

End-to-End Labeling

This dimension addresses the combined needs for labeling and packaging across the entire product lifecycle.

Stakeholders involved in both supply chain labeling and product packaging frequently use much of the same content, images, warnings, translations and phrases for both purposes. Optimizing this dimension requires you to have the most up to date content for both, which is why it is important to have a common

approach to review and approve any data and images. Ultimately, an end-to-end approach offers new levels of control, visibility and efficiency for managing labels and packaging artwork, enabling companies to eliminate bottlenecks, reduce time to market and ensure compliance.

|

|

Stage 1 REACT |

Stage 2 MANAGE |

Stage 3 INTEGRATE |

Stage 4 ORCHESTRATE |

Stage 5 EXTEND |

|

|

FOUNDATIONAL DIMENSIONS |

Standardization |

Disparate or homegrown solutions with no identified corporate standard or processes for labeling across the enterprise. |

Beginning to implement a single solution, along with processes across primary locations. |

Single standard has been adopted and legacy systems are being updated to meet new labeling standards. |

Adoption of one standard for labeling including processes, templates and data has been implement- ed across the organization. |

Adoption of one standard for all labeling and labeling processes, driven from HQ, that includes external partners and suppliers across the globe resulting in increased efficiencies and greatly reduced maintenance. |

|

Centralization |

Single location – with local oversight and limited adherence to corporate standards. |

Multiple locations with silo deploy- ments resulting in limited control over consistency and standards across business units. |

Centralized in HQ with multiple linked locations responsible for enforcing consistency at the local level only. |

Centralized in HQ with failover or ability for locations to run independently - enforcing consistency across organization, adherence to standards and universal changes throughout organization. |

Centralized in HQ with failover or ability for locations and partners to run independently – enforcing consistency across organization, adherence to standards and universal changes both internally and externally with partners. |

|

|

End-to-End Labeling |

No perceived awareness of value of integrated Enterprise Labeling and Artwork Management. |

Looking to address the overlap of shared content and processes between supply chain and packaging artwork. |

Limited integration between Enterprise Labeling and Artwork Management for some processes. |

Full integration, including shared content manage- ment, workflow and approvals, across Enterprise Labeling and Artwork Management. |

Standardized on a single, digital platform that enables businesses to create, manage and print complex labeling and packaging artwork and scale across their global enterprise, including suppliers and partners. |

|

Figure 3. Foundational Dimensions

OPERATIONAL DIMENSIONS

This Operational category of the Enterprise Labeling Maturity Model focuses on the physical execution of labeling within an organization. It highlights how labeling actually works and interoperates within your broader ecosystem measuring how well your labeling solution works with existing business systems, databases and applications, including devices used for printing and output. Here the model examines how labeling content is accessed and delivered through automation and integration with key data sources, and ultimately how it culminates with printing and output of your labels.

Automation

Replacing manual processes with automated processes driven by digital solutions offers new levels of control and consistency over labeling. Automation of labeling can be achieved by supporting transactional initiated labeling, along with configurable business logic which is essential in supporting variations and volume. Empowering business users to create and update labels without relying on IT services and leveraging automated approval workflows enables proactive label management, eliminates bottlenecks, and ensures consistency and compliance.

Integration

Integrating labeling with existing business applications offers a range of strategic advantages. Labeling that leverages existing business processes and vital data sources supports greater levels of label accuracy and consistency, while eliminating duplicate data and the need to retrain users. Initiating labeling transactions from enterprise applications and using data from a source of truth supports labeling complexity while vastly reducing the number of label templates. Integration is vital in ensuring accuracy, improving customer response times, and meeting regulatory requirements.

Printing & Output

The ability to output labels and documents across a diverse set of print devices in the time required to meet shipping and production requirements is vital. Independent of print make or model, supporting the rigors

of global label printing requires that you optimize speed and network efficiency to print labels quickly and efficiently. Native print drivers, designed for specific printers and printer languages, allow for optimum print performance at both headquarters and remote locations. As digital technologies evolve and as the need for more label data spikes, companies are using e-labeling as a means to improve customer experience, meet requirements and reduce the cost of printed labels and documents.

|

|

Stage 1 REACT |

Stage 2 MANAGE |

Stage 3 INTEGRATE |

Stage 4 ORCHESTRATE |

Stage 5 EXTEND |

|

|

OPERATIONAL DIMENSIONS |

Automation |

All labeling is manual, resulting in time consuming, error-prone processes. |

Scanning and user entry triggers labeling, along with limited use of labeling related workflows. |

Labels triggered from enterprise applications and on-demand labeling applications, with some automated workflow processes. |

Use of business logic from enterprise applications or on-demand business logic to guide labeling, along fully automated workflows throughout organization. |

Extending automation with logic and labeling related workflows to supply chain partners, designers, customers, and suppliers. Business users can easily access and update labels. |

|

Integration |

No integration or reliance on exports from enterprise applications that may result in lack of accuracy and consistency. |

File sharing, data base lookup integration with minimal use of dynamic content. |

Integration with one application to accommodate for some variable content on labels. |

Bi-directional integration with one or more applications to accommodate complete data-driven labeling triggered on either end - visibility within ERP. |

Bi-directional, centralized, with multiple integration points at local production and external partner sites, offering full dynamic labeling across supply chain. |

|

|

Printing & Output |

Manually driven label printing, uses Windows drivers that may limit the ability to meet high volume requirements. |

Some use of native printer drivers to reduce traffic and maximize print speeds. |

Primarily uses native drivers but with limited ability to print to non-network connected printers. Printing may include labels and related documents. |

Manage high volume printing and print queues with full ability to print to non-network connected printers. Document printing becomes more important and e-labeling capabilities become a focus for a portion of the business. |

Optimized, high-volume printing with the option of extending printing to remote sites and supply chain partners, while maintaining the same level of performance and quality as networked devices. Document printing and e-labeling capabilities are extended to the entire business. |

|

Figure 4. Operational Dimensions

GOVERNANCE DIMENSIONS

The final category of the Enterprise Labeling Maturity Model is Governance, which involves oversight, management, and control of labeling. Governance measures the ability to create new efficiencies and drive process improvements throughout an organization which can impact the bottom line. It also includes compliance with customer and regulatory requirements while offering expanded visibility into labeling processes. Governance also spotlights the role that ownership and key stakeholders play in labeling as part of an overall supply chain strategy.

Compliance

This dimension covers evolving customer demands, industry standards and regulations that define how your products are developed, marketed, shipped and disposed. Labeling requirements are more demanding than ever and organizations must make sure their labeling can keep up. Compliance examines the ability to

manage complex, variable data and label formats to meet current regulatory, regional and customer demands. Ensuring compliance with formatting requirements, barcodes, logos, languages, warnings and product information allows companies to avoid hefty fines and business disruption while supporting the ability to enter new markets.

Visibility & Oversight

Core to governance is having visibility into areas where labeling is both working as planned as well as areas where problems exist and change is required. Employing advanced analytics and real-time reporting to offer visibility into label creation, use and output provides a platform for auditing, assessment and continuous improvement. With access to advanced analytics and real-time reporting, users are able to gain visibility into constantly changing yet vital information including labels, printers, print jobs, users and audit data. These insights drive improvements to labeling processes as well as driving future supply chain and

labeling investments.

Ownership

As companies extend their global operations, labeling has become more prominent involving multiple departments and stakeholders and requiring new levels of attention. This includes an expanded focus by executives who view labeling as a strategic differentiator. This differentiation is driven by the positive bottom line results that can be achieved by reducing maintenance costs, avoiding fines due to non-compliance and

preventing supply chain disruption.

|

|

Stage 1 REACT |

Stage 2 MANAGE |

Stage 3 INTEGRATE |

Stage 4 ORCHESTRATE |

Stage 5 EXTEND |

|

|

GOVERNANCE DIMENSIONS |

Compliance |

Not able to comply with customer and/or regulatory labeling require- ments if needed. |

Able to comply with some requirements but entails significant time and manual intervention. |

Able to comply with most requirements by leveraging some business logic and automated processes. |

Able to easily comply with any existing customer and regulatory requirements, as well as multiple languages and regions, through automated processes and business logic. |

Able to easily comply with any customer and regulatory requirements, as well as multiple languages and regions, through automated processes and business logic – while also being able to easily adapt to any new requirements. |

|

Visibility & Oversight |

Lack of visibility into label printing and process, limiting opportunity for process improvements. |

Limited visibility at certain locations, and across the enterprise - could entail multiple solutions. |

Single approach to visibility, applied to portions of the organization with limited awareness at the executive level. |

Adoption of business intelligence (BI) for increased visibility throughout organization. Including visibility to audit data and flexibility to create custom reports for increased awareness at the executive level. |

BI with real time visibility internally and externally (partners and suppliers), offering complete view of all user activity with advanced insight into labeling to drive process improvements with impact on the bottom line - resulting in oversight at the executive level. |

|

|

Ownership |

Labeling is owned at the location level with IT as the main stakeholder. |

Labeling is owned at the location level with representation from both IT and business stakeholders. |

Labeling has multiple departments and stakeholders that share responsibility. |

Labeling is a defined group or organization that offers a strategic service to parts of the organization and enforces standards. |

The labeling organization has ownership and meets global requirements across the organization, as well as supply chain partners, suppliers and customers. |

|

Figure 5. Governance Dimensions

Prioritizing Dimensions Towards Enterprise Labeling Maturity

The degree of focus that a business places on developing the nine dimensions varies based on the level of maturity desired, as well as the structure and scope of the business. Below you will find the most common levels of priority for each dimension at each stage. This helps to assess efforts as you advance your Enterprise Labeling initiatives (see Figure 6).

|

|

Stage 1 REACT |

Stage 2 MANAGE |

Stage 3 INTEGRATE |

Stage 4 ORCHESTRATE |

Stage 5 EXTEND |

|

|

FOUNDATIONAL |

Standardization |

MEDIUM |

MEDIUM |

HIGH |

HIGH |

HIGH |

|

Centralization |

LOW |

LOW |

MEDIUM |

HIGH |

HIGH |

|

|

End-to-End Labeling |

LOW |

LOW |

MEDIUM |

MEDIUM |

HIGH |

|

|

OPERATIONAL |

Automation |

LOW |

MEDIUM |

HIGH |

HIGH |

HIGH |

|

Integration |

LOW |

MEDIUM |

HIGH |

HIGH |

HIGH |

|

|

Printing & Output |

HIGH |

HIGH |

HIGH |

HIGH |

HIGH |

|

|

GOVERNANCE |

Compliance |

HIGH |

HIGH |

HIGH |

HIGH |

HIGH |

|

Visibility & Oversight |

LOW |

LOW |

MEDIUM |

HIGH |

HIGH |

|

|

Ownership |

LOW |

LOW |

MEDIUM |

HIGH |

HIGH |

|

Figure 6. Priority by Stage and Dimension

Determining Your Stage of Enterprise Labeling Maturity

Loftware’s Maturity Model is intended to offer guidance on how to move your current labeling forward by providing a stage-based evaluation of your maturation path for achieving efficiency in Enterprise Labeling. This self-assessment tool enables you to map out your current state and offers respective improvement measures which can be taken to manage continuous improvement for your labeling. You can measure the effectiveness of your labeling and determine what capabilities are needed to increase labeling efficiencies and enable business transformation.

Key labeling stakeholders can complete the survey on their own and get a customized report outlining your results and recommended next steps.

Loftware is the global market leader in Enterprise Labeling and Artwork Management solutions with more than 5,000 customers in over 100 countries. Offering the industry’s most comprehensive digital platform, with SaaS, cloud-based and on-premise solutions, Loftware redefines how enterprises create, manage and print complex labeling and packaging artwork and scale across their operations. Loftware solutions integrate with SAP®, Oracle® and other enterprise applications to produce mission-critical barcode labels, documents, RFID smart tags and packaging artwork. Our combined platform – whether for labeling, artwork management or both – enables customers to uniquely meet regulatory mandates, mitigate risk, reduce complexity, ensure traceability, improve time to market and optimize costs as they meet customer-specific, brand, regional and regulatory requirements with unprecedented speed and agility.

© Copyright 2000-2025 COGITO SOFTWARE CO.,LTD. All rights reserved